Aerodynamics

Aerodynamic and Structural Seals for Commercial Aviation

Aerodynamic and structural seals are among the invisible but crucial components of modern commercial and business aircraft. They ensure that the fuselage remains airtight, internal cabin pressure is maintained, aerodynamics are optimized and sensitive components are protected from environmental influences.

The stresses are enormous: extreme temperature differences between the runway and cruising altitude, constant UV radiation at high altitudes, aggressive chemicals such as de-icing fluids or hydraulic oils - a seal must be able to reliably withstand all of this. At the same time, they must be flexible, durable and lightweight in order to support the energy efficiency of the aircraft.

Freudenberg Sealing Technologies develops and produces seals that meet precisely these requirements. With state-of-the-art materials, precise profile geometries and comprehensive know-how in the aerospace sector, we ensure safety, efficiency and a long service life.

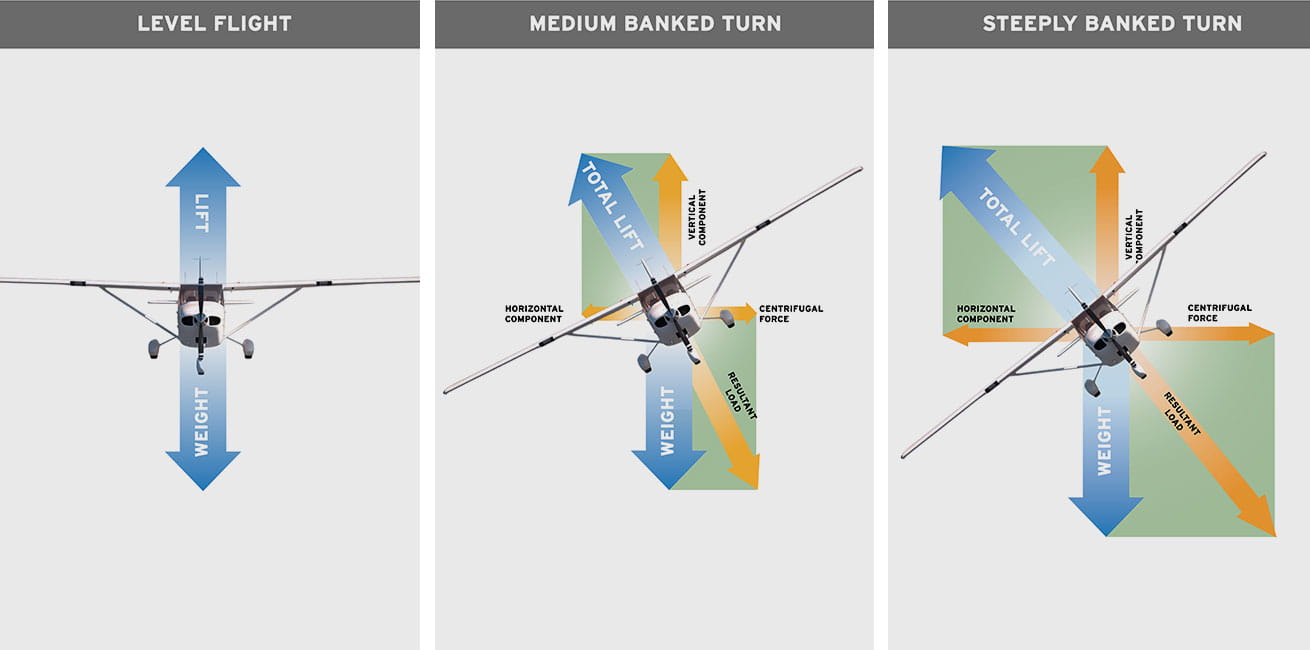

Why are Aerodynamic Seals and Structural Seals Indispensable?

Seals in aircraft structures perform more than just a sealing function. They ensure the pressure stability of the cabin, prevent air and liquid leaks and contribute to the reduction of air resistance, vibrations and noise.

Missing or inadequate seals would not only reduce comfort, but also massively jeopardize operational safety. Minimal pressure loss can affect the integrity of the cabin, poor aerodynamics lead to higher fuel consumption, and unfiltered vibrations affect the service life of components.

Freudenberg Sealing Technologies has been developing solutions tailored to the extreme requirements of commercial aviation for decades - certified to AS/EN9100 and tested to DO-160.

Typical Challenges for Structural Seals in Aviation

Aerodynamic and structural seals are particularly demanding. The key requirements include:

- Extreme temperatures: from icy -50 °C at high altitudes to +80 °C or more when rolling on hot asphalt.

- UV exposure: Permanent radiation at cruising altitude puts a lot of strain on conventional materials.

- Chemical resistance: Fuels, hydraulic fluids, de-icing agents and cleaning agents attack many materials.

- Mechanical stress: Vibrations, micro-movements and pressure changes lead to material fatigue.

- Noise and vibration damping: Seals actively contribute to minimizing vibration transmission and increasing cabin comfort.

- Regulatory requirements: Strict certifications such as AS9100 or EN9100 are standard requirements.

Freudenberg Sealing Technologies meets these challenges with comprehensive sealing concepts that optimally combine materials, geometries and manufacturing processes.

Where are Aerodynamic and Structural Seals Used?

The Freudenberg Sealing Technologies portfolio for aerodynamic and airframe seals includes

- Door and window seals: Doors could include Pax doors, but also for baggage and maintenance access panels. Also may wish to comment the difference among commercial pressurized cabins for commercial and business aircraft above 10,000 ft, but also offer solutions for recreational aircraft without pressurization.

- Wing and control surface seals: reduce air resistance, stabilize the air flow and ensure mobility.

- Fuselage and panel seals: ensure structural integrity and prevent leaks.

- Specialized aerodynamic profiles: individually adapted to aircraft models and aerodynamic requirements.

All products are optimized for lightweight construction, precisely manufactured and designed for long service intervals.

Which Materials Ensure the Performance of Aircraft Seals?

The choice of material is decisive for the performance of a gasket. Our material development offers:

- Advanced elastomers: High flexibility, low permanent deformation, long service life.

- Silicone compounds: Excellent resistance to high temperatures and ageing.

- Fluoropolymers: Superior protection against UV radiation, aggressive liquids and chemicals.

- Specialized aerodynamic profiles: individually adapted to aircraft models and aerodynamic requirements.

The combination of these materials, optionally reinforced with fabrics or other strengthening layers, results in sealing systems that deliver increased abrasion resistance and toughness and operate reliably even in the most extreme flight environments.

Aerospace Sealing Product Range

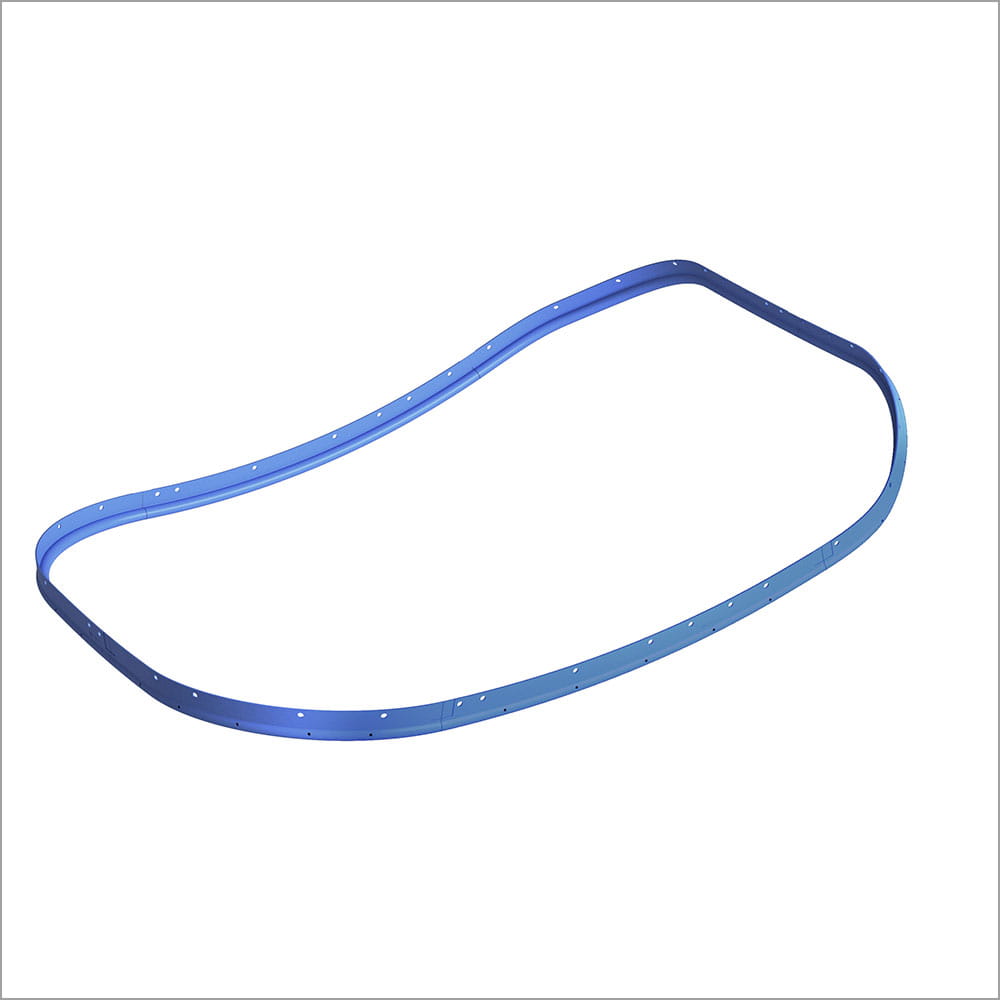

Cargo Door Seals

Aircraft door seal from Freudenberg Sealing Technologies, ensuring airtight closure, cabin pressure stability, and passenger safety.

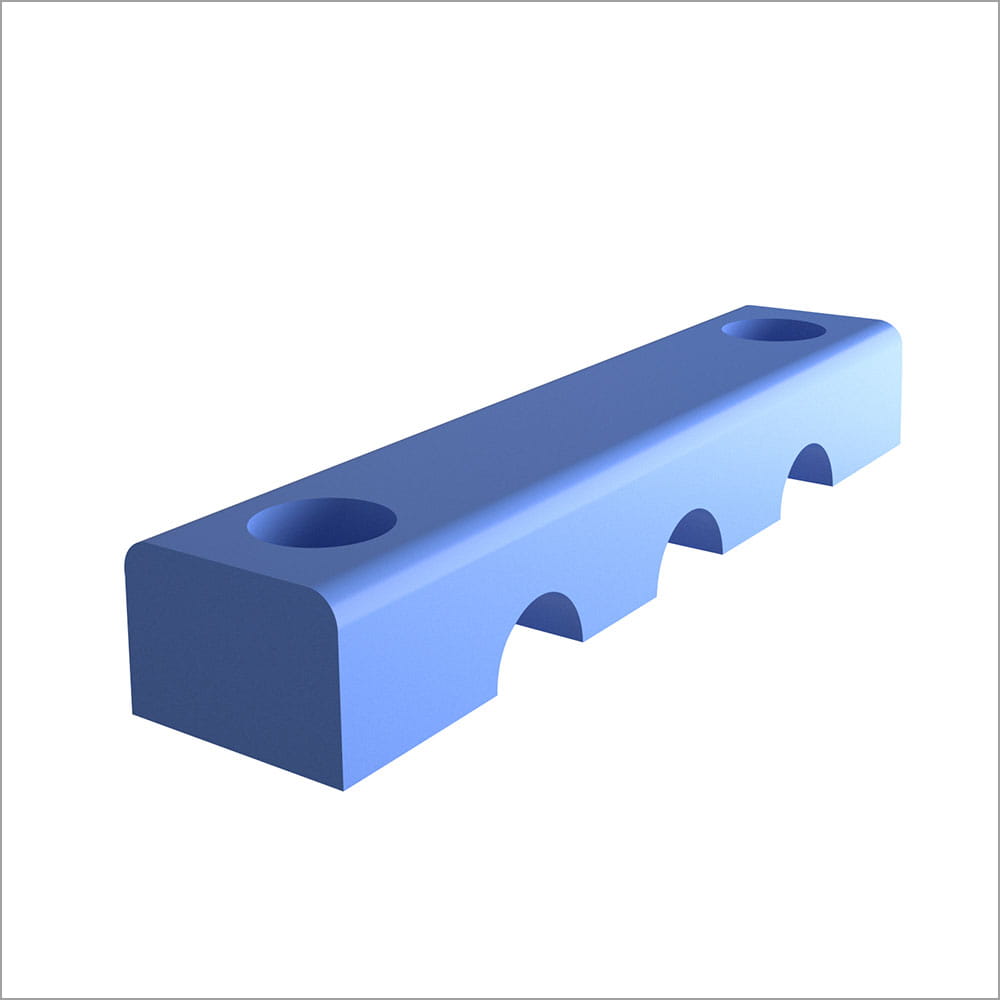

Clamp Blocks

Clamp Blocks are components used to secure and organize tubing and wiring in aerospace applications, ensuring stability and protection against high-vibration and extreme temperature conditions. They are essential for maintaining the integrity and performance of various aerospace systems.

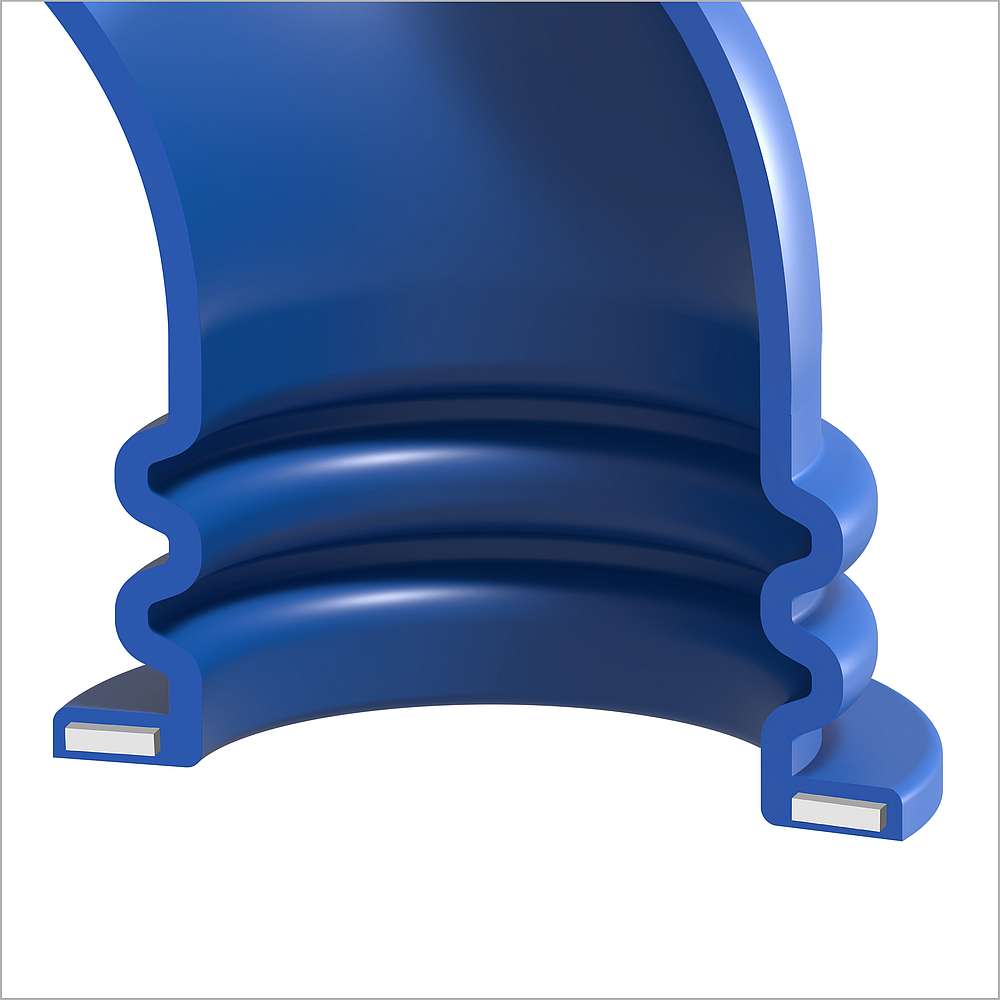

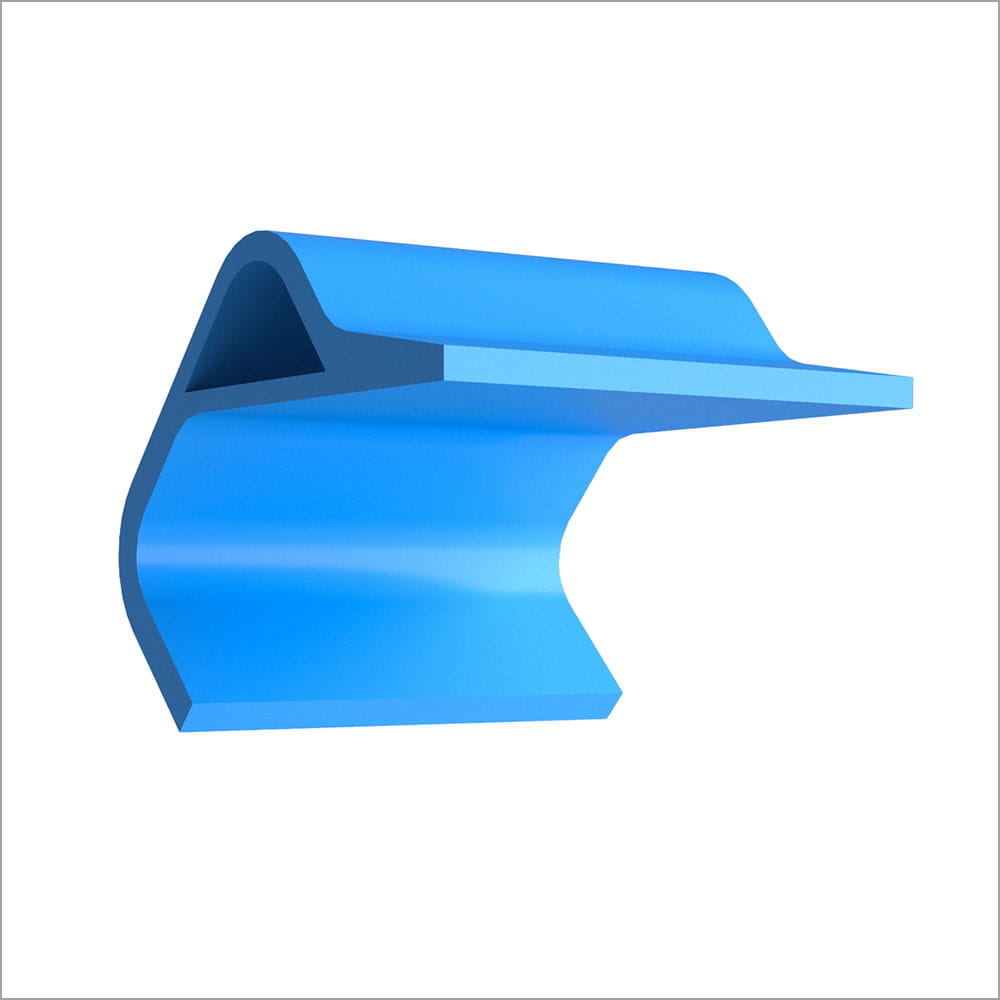

D-seal with channel retention

A D‑profile engineered to lock into a retention channel for stable positioning under vibration and load, delivering consistent compression and low air leakage along doors, panels, and fairings. Durable elastomers help maintain sealing performance over long service intervals.

D-seal with pull throughs

Features integrated pull‑throughs for positive mechanical retention and fast installation, ensuring the seal stays seated through thermal cycling and pressure changes. Ideal for perimeter applications that demand reliable, repeatable closure forces.

Flexible Fluid Transfer Solutions

Our elastomeric ducts, offering flexibility and lightweight construction, facilitate smooth liquid or gas transfer between rigid interfaces. Engineered for extensive movements and tolerances, they exhibit fatigue resistance. Utilizing proprietary materials, these ducts guarantee prolonged durability in extreme conditions and aggressive environments, with the option for added fire protection.

Extruded profile

Custom extruded profiles tailored to complex airframe contours provide a clean aerodynamic surface and dependable gap sealing. Designed for lightweight durability with resistance to UV, ozone, and typical aerospace fluids.

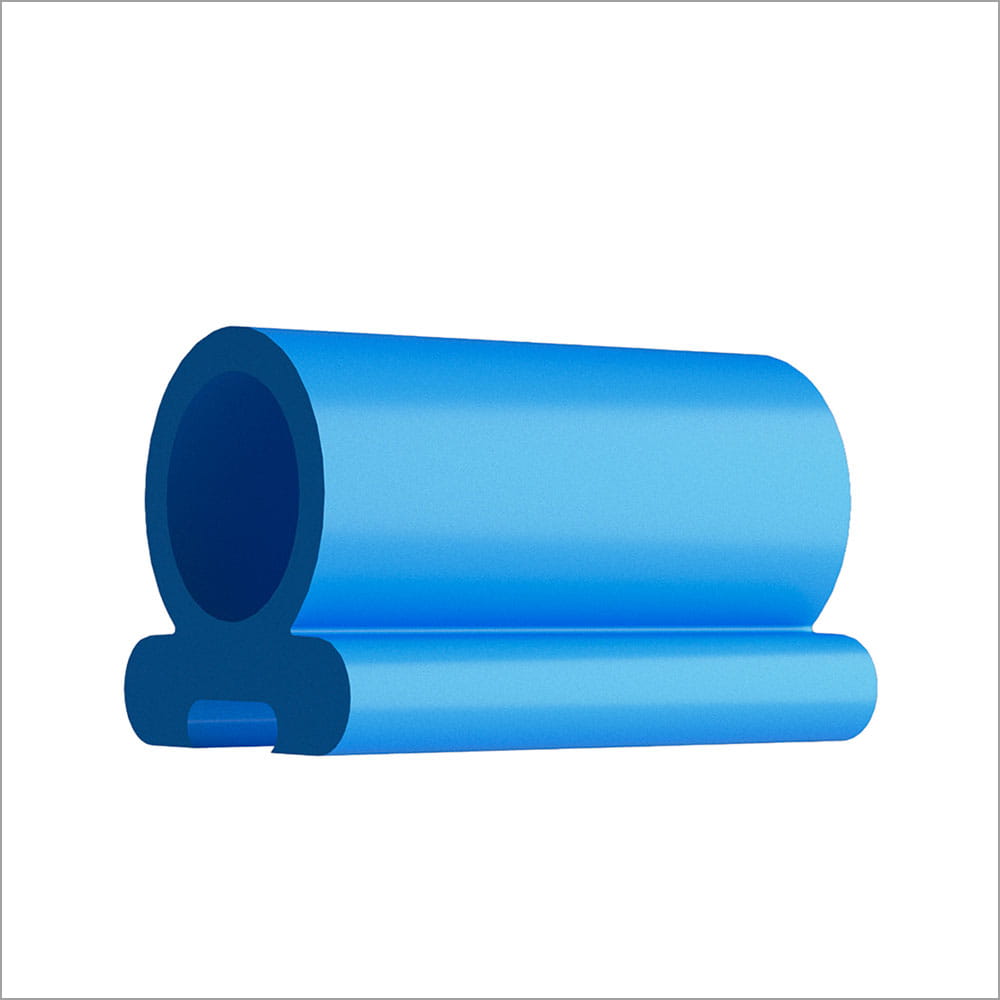

Omega bulb seal

An omega‑shaped bulb offers high conformability and rebound to accommodate tolerances while minimizing air leakage. Commonly used around hatches and access panels to damp vibration and support smooth, low‑drag interfaces.

P-seal

The compact P‑section provides efficient edge sealing along skins and panels, helping reduce noise and drag. Available in aerospace‑grade elastomers for stable compression set and long‑term resilience.

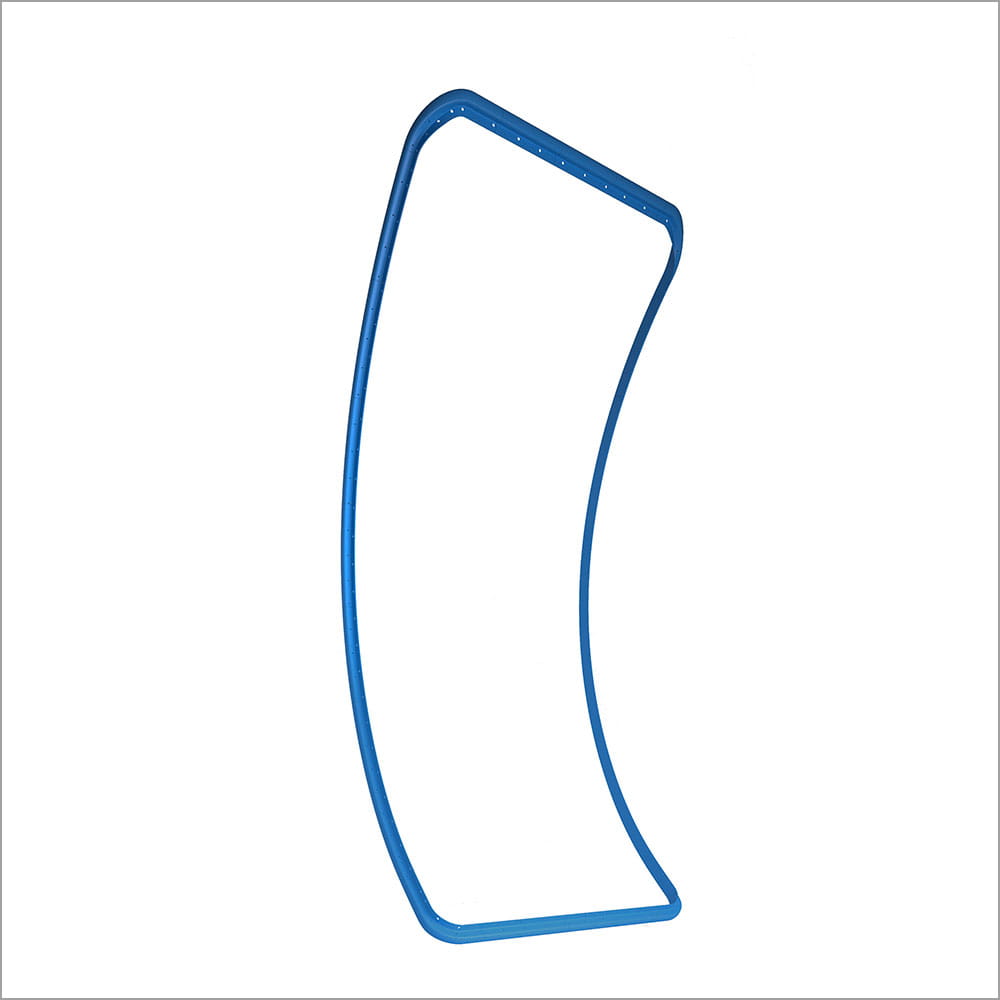

Passenger Door Seal

Precision‑molded, perimeter seals for passenger doors that aid cabin pressure retention and acoustic comfort while supporting low operating and closing forces. Engineered for repeatable performance across wide temperature ranges.

Rod T Seal

A T‑anchored rod profile combines robust mechanical retention with reliable lip contact to block air and moisture ingress. Suited for linear tracks where fast assembly and serviceability matter.

Adaptable Sealing Solutions

Our silicone tape forms an airtight, watertight seal around electrical connections, bonding permanently within 24 hours. With no-adhesive technology, it allows easy, clean re-entry without substrate bonding. Additionally, it's available with fabric reinforcement, enhancing tear resistance and flame retardancy, ideal for applications requiring durability, such as hot air ducting.

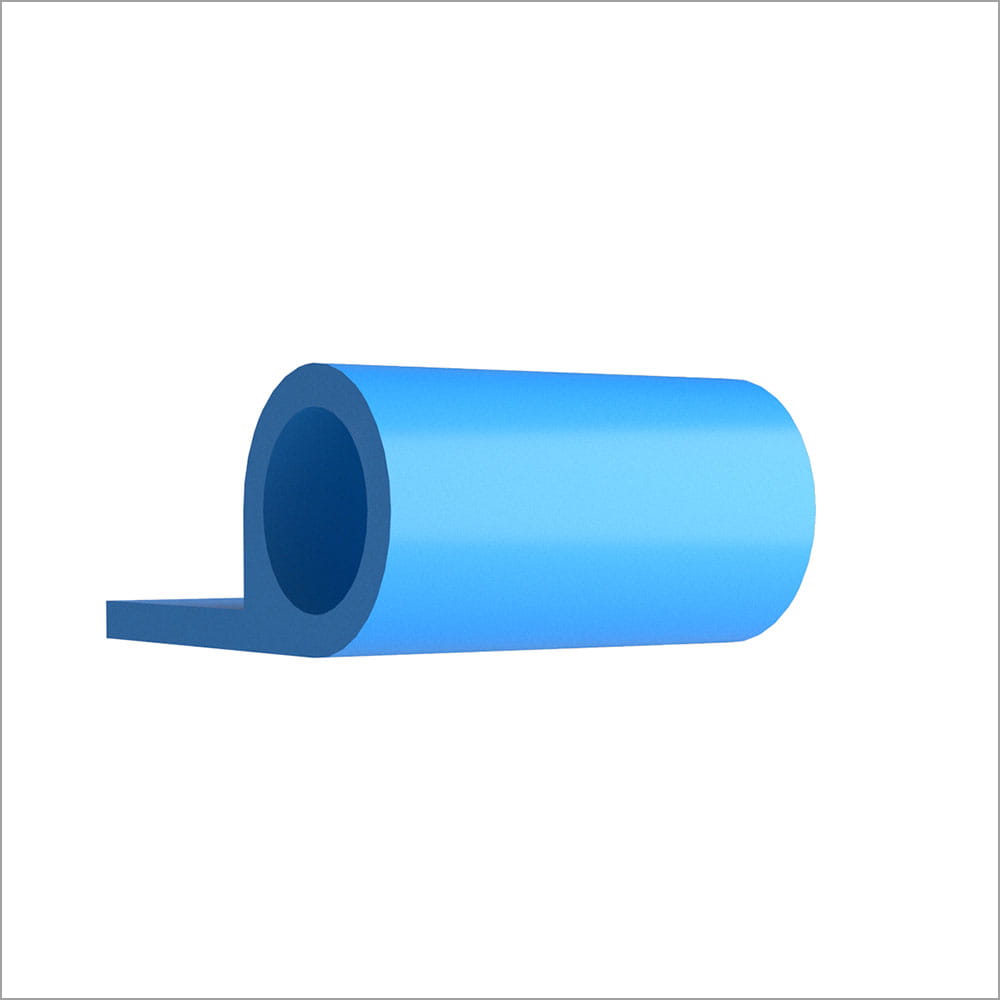

Simple Omega Seal

A streamlined omega cross‑section that delivers dependable compression sealing in tight envelopes. Balances sealing force with easy door/panel actuation to preserve user ergonomics.

T-Seal Extrusion

T‑shaped extrusions seat securely in channels to create a neat, stable edge seal with minimal flutter. Formulated for consistent performance under temperature swings and exposure to aviation fluids.

Y-Seal

Dual sealing lips in a Y‑profile provide redundancy and excellent misalignment compensation, maintaining a tight seal with low closing force. Effective for long runs where dimensional variation is expected.

Elevating Aviation Standards

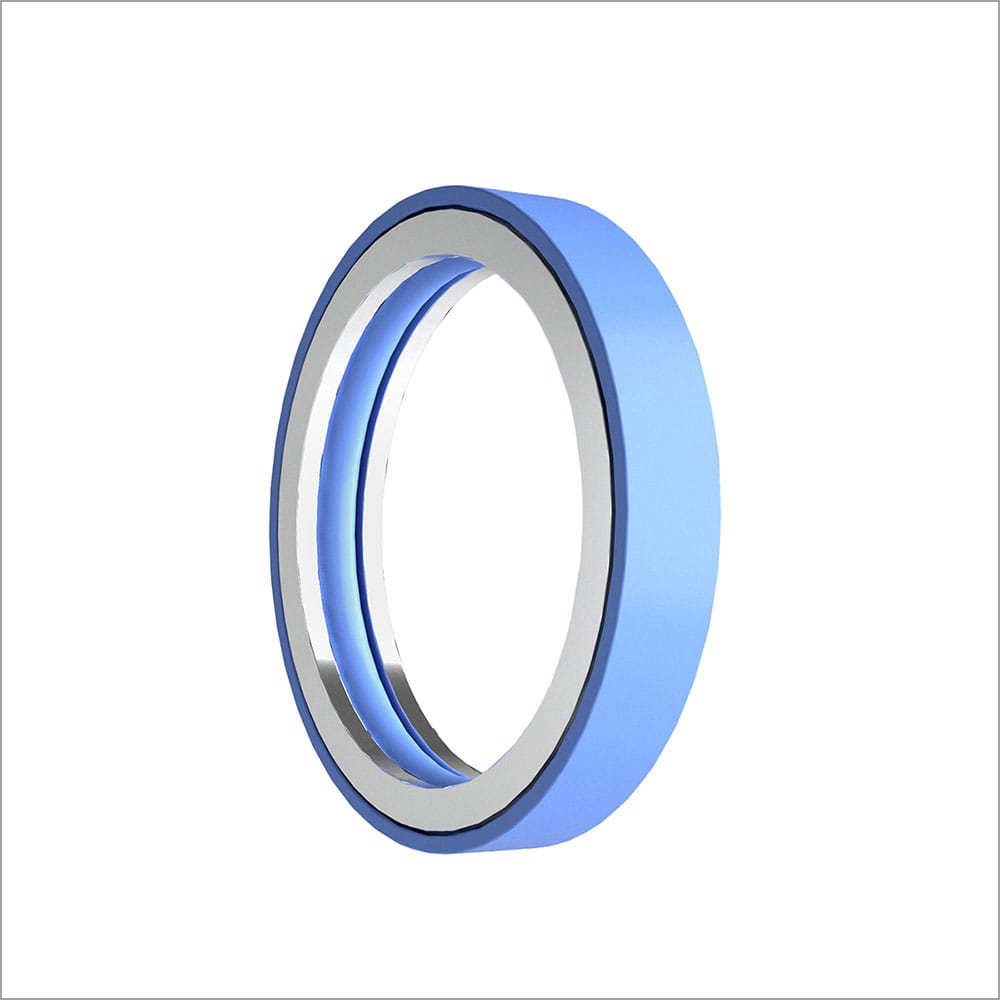

Our O-rings excel in aircraft functions, delivering Six Sigma quality and exceptional resistance to temperature and chemicals. Available in AS568, BS1806, and metric sizes, our exclusive elastomer formulations promise versatility across diverse applications, meeting industry demands with unparalleled performance.

Back-up rings

Prevent the extrusion of O-rings under high pressures and increase their service life.

Did you already know?

- Seals in the wing area actively help to reduce drag - even a few percent increase in efficiency saves thousands of liters of fuel every year.

- Window seals are not only responsible for maintaining pressure, but also act as a noise and vibration barrier.

- Modern sealing materials can withstand temperature peaks of over 200 °C without losing their elasticity.

Why Should You Choose Freudenberg Sealing Technologies?

Freudenberg Sealing Technologies has been a reliable partner to the international aviation industry for many years and works closely with leading OEMs such as Airbus and Boeing. This long-standing industry know-how flows into every new sealing solution. Simulations and co- engineering are used to create customized profiles and geometries that are precisely tailored to the requirements of modern aircraft.

Customers can rely on certified quality: Our products meet all relevant aviation norms and standards - from development to series release. And we also provide reliable support after delivery: with spare parts supply, technical support and long-term service, we ensure the performance of our sealing systems throughout their entire life cycle.

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new