Landing Gear & Wheel Brake

Sealing Solutions for Landing Gear and Wheel Brake Systems in Commercial Aviation

Safety during take-off, landing and taxiing

Landing gear and wheel brake systems are among the most safety-critical components in commercial aircraft. They bear the entire weight of the aircraft during take-off, landing and taxiing on the ground. Extreme mechanical forces, high temperature peaks and aggressive environmental influences such as moisture, de-icing agents and salt are all at play.

Reliable sealing solutions are crucial to prevent leaks, protect hydraulic systems and ensure long-term operational safety. Freudenberg Sealing Technologies develops products and materials that meet these challenges - for greater safety, efficiency and sustainability in commercial aviation.

Historical milestone

From grinding spur to high-tech landing gear

Early airplanes braked with simple wooden or metal grinding spurs. It was not until the 1930s that the retractable landing gear became established, which drastically reduced drag and is still the standard in aviation today. Modern landing gears are highly complex, hydraulic-electric systems.

Why are Seals so Critical for Landing Gear and Wheel Brakes?

Extreme loads occur during take-off and landing, which could not be controlled without reliable sealing systems. Seals prevent leaks in hydraulic systems, protect against corrosion, dirt and failures caused by thermal peaks. Seals must function reliably, especially in the nose wheel landing gear (tricycle landing gear), even under high lateral loads.

How Do the Landing Gear and Wheel Brake Systems Work in the Flight Phases?

Take-off

The landing gear absorbs the full weight of the aircraft, with kinetic energies of hundreds of tons. The wheel unit, shock absorbers and support structures act as central components. Seals in actuators and hydraulic systems ensure the transfer of energy and enable stable, safe acceleration.

Flight

After retraction, the chassis remains exposed to high pressure and temperature fluctuations. Seals protect sensitive components and ensure functionality until extension.

Landing

During landing, extreme impact forces act on the wheels and brakes. In addition to high pressure loads, strongly fluctuating lateral forces also act on the wheel and damping systems. Seals protect hydraulic cylinders and brake components against leaks - even during temperature peaks in the high-performance range. Emergency braking systems intervene redundantly in an emergency.

Rolling on the ground

Taxiing exposes chassis and brake systems to continuous loads. Strong vibrations and high frequencies at the piston rods generate briefly increased temperatures at the sealing edge. Shimmy dampers are also used here to suppress uncontrolled vibrations at the nose wheel. Without high-performance materials, this can lead to increased abrasion. Precise seals from Freudenberg Sealing Technologies prevent this wear and ensure stability, steering capability and minimal friction losses.

From Shock Load to Corrosion: Challenges in Detail

- Mechanical loads and wear: Shock and shear forces during touchdown/braking. High pressures and alternating lateral forces in shock absorbers and wheel suspensions.

- Temperature peaks during braking: within seconds several hundred °C and thus great thermal stress for sealing lips and materials.

- Vibrations and micromovements: Resonance and high- frequency vibrations increase friction and localized heating. This increases the risk of stick-slip and edge wear.

- Media and corrosion: Moisture, road salt and de-icing agents attack materials. This places high demands on chemical resistance and corrosion protection.

- Weight and efficiency: weighing up lightweight construction requirements versus stability. Friction optimization to reduce energy consumption and operating costs.

Did you know?

- Aircraft brakes can get hotter than 300 °C - comparable to volcanic rock.

- Although tires appear small in relation to the aircraft, main landing gear tires reach diameters of 1.1-1.4 m.

- When a long-haul jet touches down, it bears the load of over 20 fully loaded trucks.

Our Products for Chassis and Brake Systems

- High-performance seals: for hydraulic cylinders, actuators and transmissions

- O-rings, lubricant seals, wheel seals, PTFE seals, T- seals: also in large dimensions O-Ring T-Seal

- Brake pads and friction materials: for reliable deceleration even in extreme heat

- Protective coatings and surface treatments: Corrosion protection against moisture, salt and chemicals

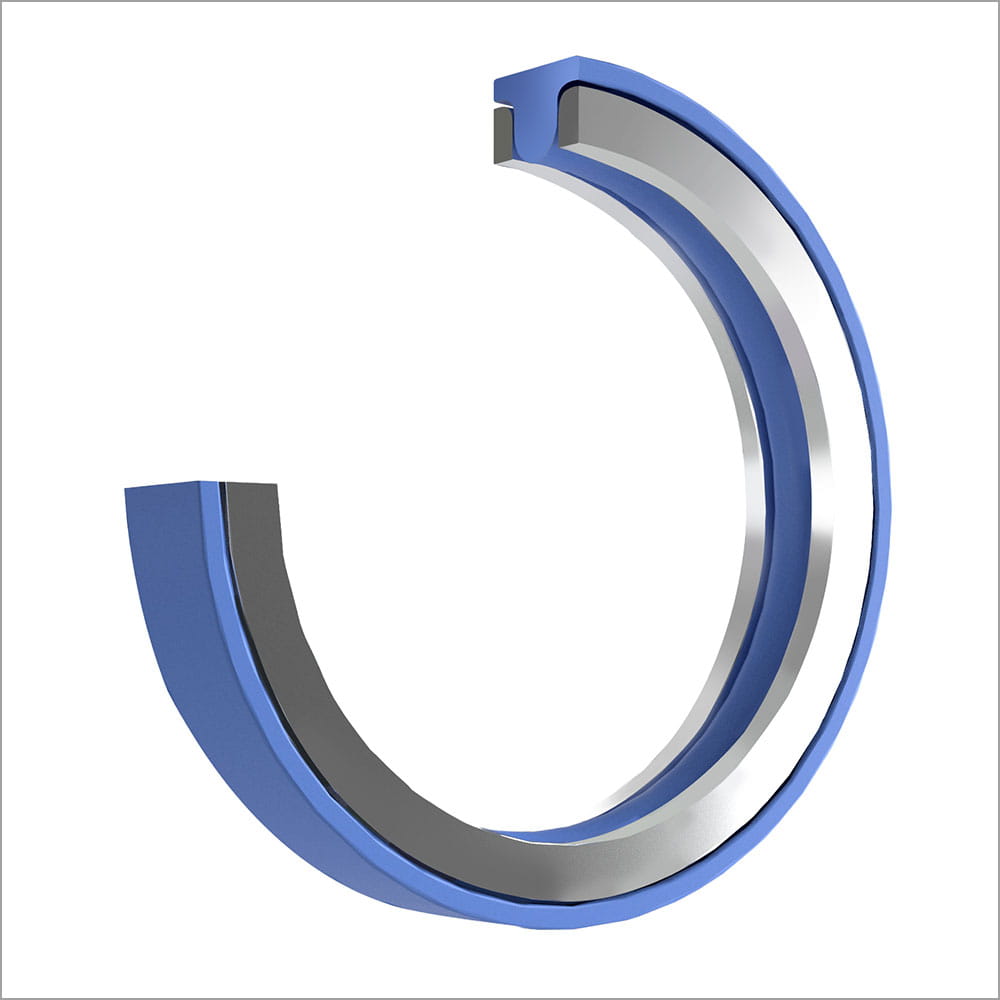

O-Rings

Universal seals, ideal for static and dynamic applications, particularly flexible and reliable under high pressure loads.

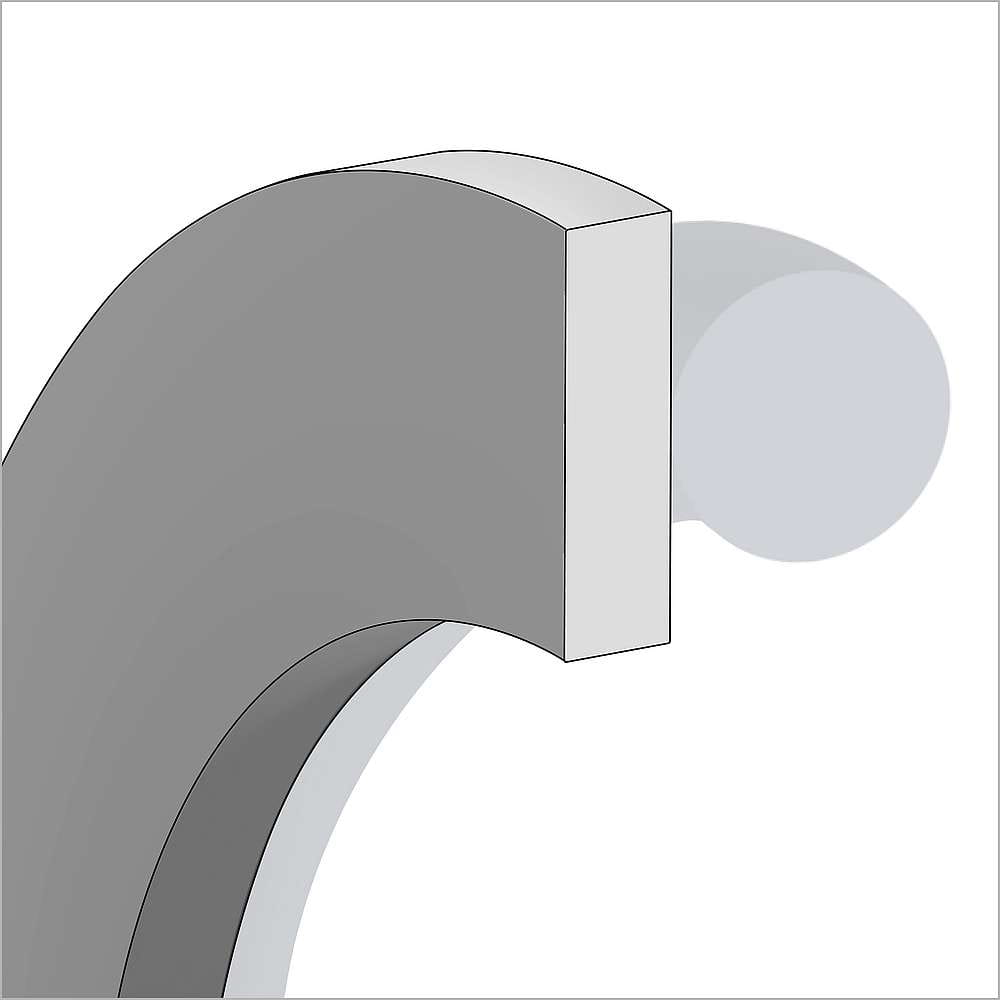

T-Seal Extrusion

T‑shaped extrusions seat securely in channels to create a neat, stable edge seal with minimal flutter. Formulated for consistent performance under temperature swings and exposure to aviation fluids.

PTFE Seals

Outstanding thermal and mechanical resistance, particularly suitable for extreme temperature and pressure conditions.

Materials for Extreme Requirements

- High-strength composite materials: high load-bearing capacity and low weight

- Corrosion-resistant alloys: Protection against aggressive environmental influences

- Advanced elastomers: flexible, resistant to pressure and temperature fluctuations

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new