Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

29.10.2025 | News

Hygienic Flange Seal for Flow Sensor

As a technology leader, Freudenberg Sealing Technologies is the specialist for innovative sealing solutions in the process industry. Our focus is on innovation and partnership. Together with our customers, we develop tailor-made materials and sealing products according to segment- or customer-specific requirements, such as approvals, Hygienic Design and CIP/SIP processes.

The customer

ifm is a group of companies that develops, manufactures, and distributes sensors, controllers, and systems for industrial automation. In the process industry, ifm offers solutions for monitoring and controlling processes

Segment & Application

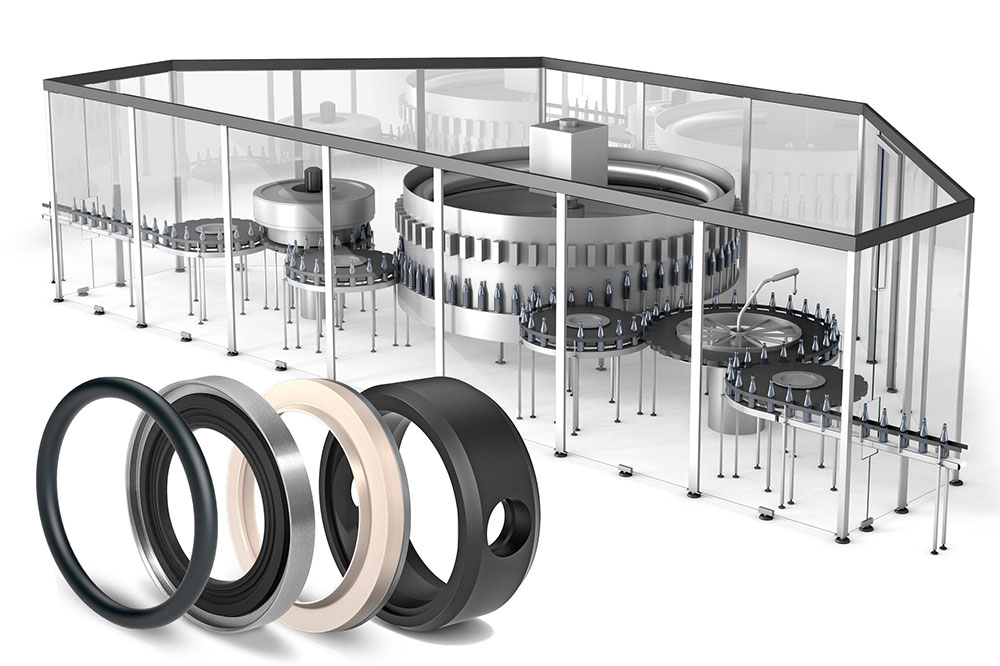

In close cooperation with our customer ifm, FST developed flange seals according to hygienic design for a new magnetic-inductive flow sensor with an innovative operating concept. This was to be designed specifically for the food industry and had to comply with industry-specific legal regulations such as FDA, EG (Reg.) 1935/2004, and 3-A Sanitary Standards.

Development & Solution

ifm was looking for a reliable and professional partner with the material expertise, know-how, and support required for the development of seals in line with hygienic design principles. FST met these requirements and supported ifm in developing a design that ensured the best possible coverage of the hygienic flange seal in the sensor‘s flow area, taking into account temperature and swelling, in order to meet the highest purity requirements.

The development process comprised several steps:

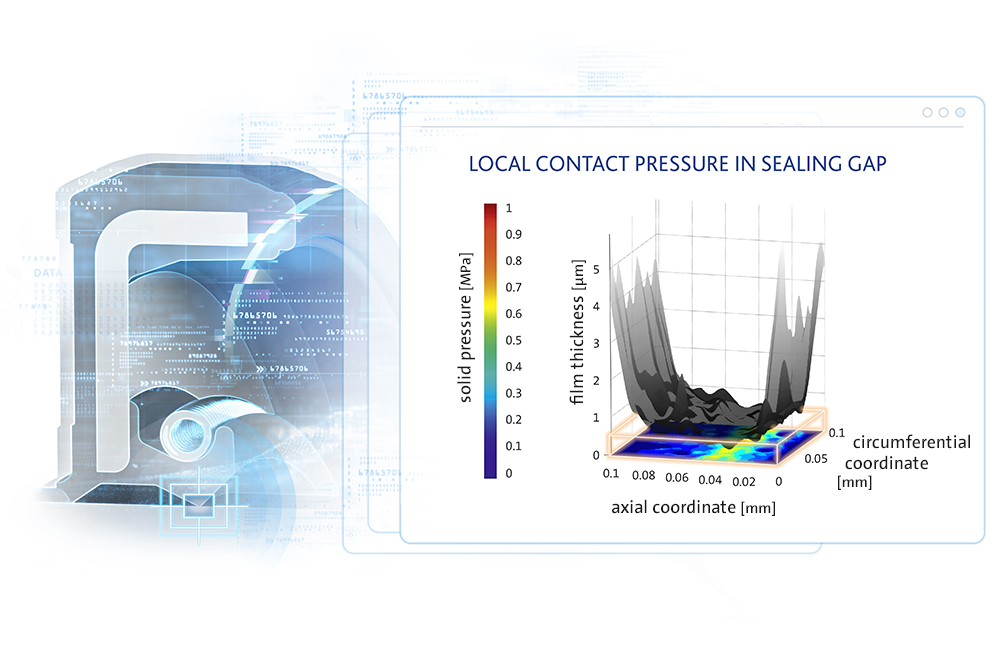

1. FEM-calculation: Thanks to the digital modeling capabilities of the finite element method (FEM), FST was able to analyze the mechanical properties of the seals in advance.

2. Prototyping: Freudenberg Xpress® Service produced the first machined prototypes required for this initial validation step. Advantage: The samples were produced using the same material intended for series production. In addition, no tool production was necessary, which saved time and money.

3. Production of near-series samples: Production-ready tooling patterns were created and subjected to final validation.

4. Series tools and series sampling: Based on positive results, the necessary series tools were created and series sampling was carried out by FST.

This step-by-step validation and verification of the development stages was key to our joint success and demonstrates the strength of the collaboration between ifm and FST.

Benefits at a Glance

-

Cleanability in accordance with DIN 10113. This standard serves to control the hygiene and cleanability of surfaces in the food industry. It helps to determine the bacterial load and to check the effectiveness of cleaning processes.

-

The seal design complies with hygienic design standards and is designed for a long service life.

-

Premium sealing materials that have the relevant approvals and conformities

-

Optimized project costs through prototyping with the Freudenberg Xpress® service and prior FEM-calculations

More news on the subject Material Expertise

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.