Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

24.11.2025 | Press release

With innovative sealing solutions without bisphenol AF, Freudenberg is setting new standards

Weinheim, November 24, 2025. In accordance with EU Directive 2024/3190, a Europe-wide ban on the use of bisphenol A (BPA) and its derivatives took effect on January 20, 2025. This decree applies to all industrial companies that produce, market or use materials that come into contact with food. The ban is based on comprehensive studies on bisphenols’ harmful health effects when they reach the human body by means of the food chain.

There are application-specific exceptions to the bisphenol A ban that are in effect for a timeframe of up to several years. Other dangerous bisphenols are excluded from the exceptions. One consequence is that an immediate and complete ban on bisphenol AF (BPAF), commonly used in the rubber sector, has been in effect since September 1 of this year in the food and beverage industry.

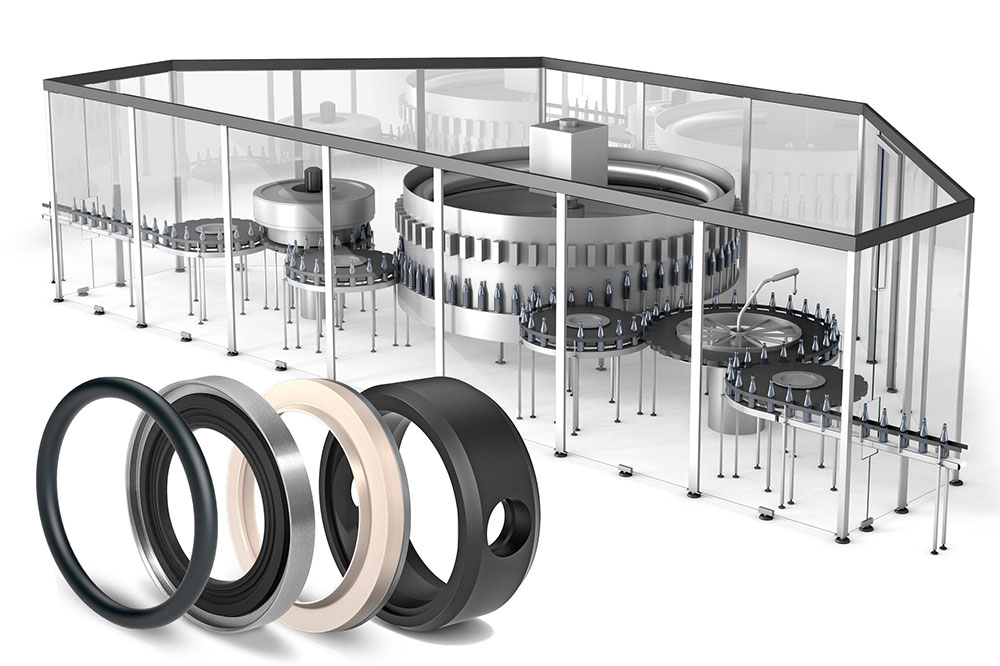

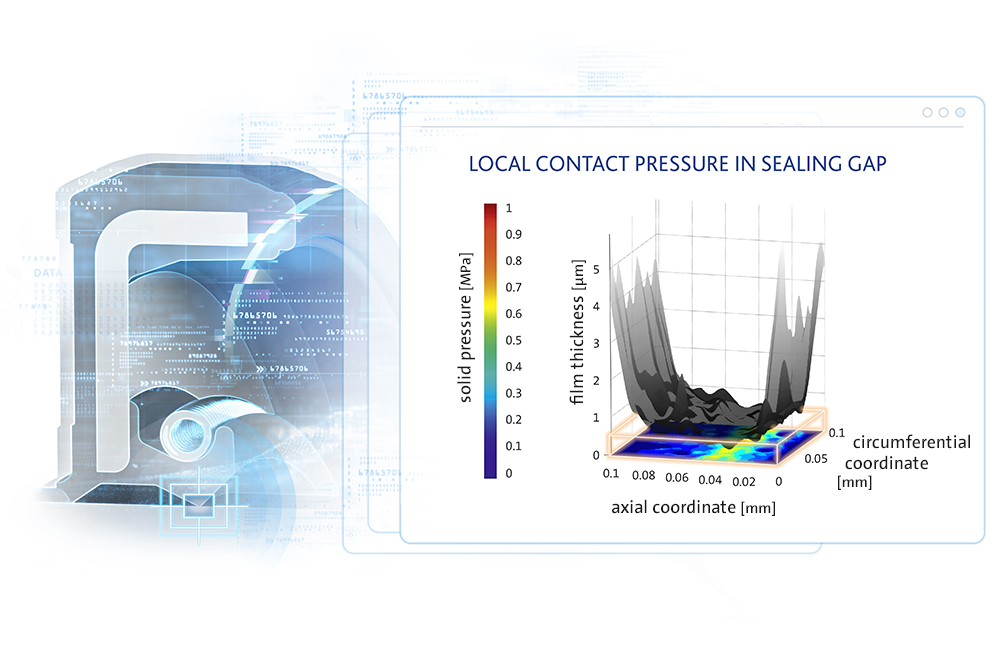

From the start, a team of experts on food contact materials at Freudenberg Sealing Technologies has been following the health-related research on BPAF’s use in the food sector. Early on, the specialists succeeded in developing BPAF-free, peroxidically cross-linked fluoro elastomers (FKM) to market-readiness – long before the new law took effect. This further expanded the company’s leadership position in the market – the use of synthetic rubbers such as FKM is crucial in high-performance, inert sealing solutions in demanding environmental conditions. Among other things, they stand out for their extraordinary chemical and thermal resistance and their long life spans. These properties are especially required in the food and beverage industry.

These elastic jacks-of-all-trades are produced in an elaborate cross-linking process that gives seals their specific characteristics. They are another example of the technological excellence that results from interdisciplinary teamwork and close cooperation with the company’s industrial customers. They give crucial impetus to the development of groundbreaking, industry-specific solutions – such as the substitution of peroxidically cross-linked materials for bisphenol AF.

Press Release Downloads

With innovative sealing solutions without bisphenol AF, Freudenberg is setting new standards

Last update: 24.11.2025

English | DOCX | 84 KB

DownloadJosh Barnett

Corporate Communications Manager

Telephone: + 1 734 354 2406

josh.barnett@fnst.com chevron_rightMichelle Klöss

Senior Manager Communications

Telephone: + 49 (0) 6201 960 5379

michelle.kloess@fst.com chevron_rightNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Material Expertise

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.