Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

13.02.2026 | News

Permeation under Control: Sealing Materials for Climate Friendly Substations

Electricity often travels long distances before it reaches consumers. To make this possible, substations rely on sulfur hexafluoride (SF₆), a protective gas used primarily as an insulating and arc extinguishing medium in high and medium voltage electrical systems. If SF₆ escapes as a result of leaks, however, it poses a serious threat to the climate: its global warming potential is around 23,500 times higher than that of CO₂. Despite its outstanding insulating properties, the gas is increasingly being phased out under strict environmental regulations, particularly in the EU. Seals from Freudenberg Sealing Technologies play a crucial role in ensuring that the gas remains safely contained where it belongs.

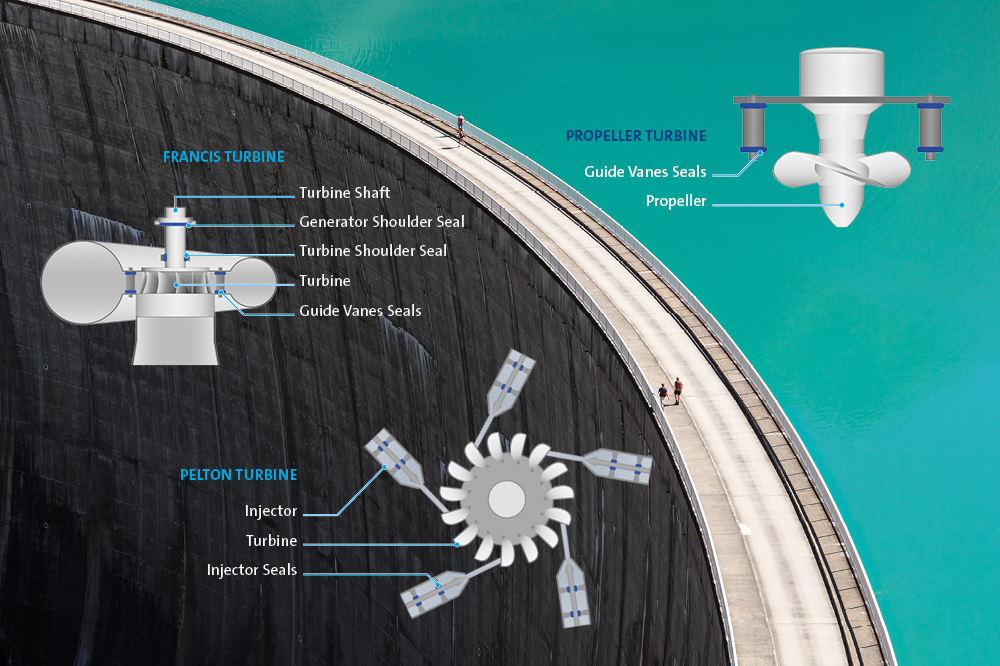

Across many countries, the expansion of renewable energy is accelerating the transformation of the power supply. For the energy transition to succeed, electricity generated by solar and wind farms as well as hydroelectric power plants must be transmitted to consumers with minimal losses. Existing power lines are therefore being supplemented with new ones, as significantly larger volumes of electricity will need to flow from windy coastal regions to inland areas in the future. Distribution and substations, which connect high voltage transmission lines to local distribution networks, are central to this process.

Substations equipped with fully enclosed, gas insulated switchgear offer clear advantages. Compared with air insulated systems, they are far more compact and can be installed inside buildings, saving valuable space - an important consideration, especially in densely populated urban areas. During switching operations, however, electrical arcs can occur. Protective gases are used to prevent such arcing or to extinguish it rapidly and reliably.

For these gases to perform their function over the long term, the seals within the system must retain them securely. For many years, the highly climate damaging SF₆ was used in gas insulated switchgear. Thanks to its relatively large molecules, the gas permeated sealing materials only very slowly. Today, however, plant operators are increasingly switching to more climate friendly, CO₂ based gas mixtures. Their much smaller molecules present a new challenge: they pass through the EPDM rubber traditionally used for seals far more easily - an effect comparable to balloons that gradually lose air over time. To counter this so called permeation, meaning the penetration, migration, and eventual escape of gases, a new material approach was required.

Freudenberg Sealing Technologies developed the solution with sealing compounds based on chlorobutyl rubber (CIIR). This material reliably retains carbon dioxide based gas mixtures, making it possible to achieve the service lives of several decades demanded by the industry. CIIR seals operate reliably across a wide temperature range, from minus 60 to plus 130 degrees Celsius, and offer excellent long term resistance to oxygen and ozone.

The exceptional sealing performance of CIIR is rooted in its material structure. Its three dimensional network of polymer molecules is significantly denser than that of conventional materials, comparable to an extremely fine meshed sieve. Even the small molecules found in CO₂ based gases struggle to pass through this tight polymer structure.

As a result, diffusion is dramatically slowed, and the point at which gas molecules desorb and escape from the outside of the seal is significantly delayed.

Explore Energy Transmission Seals

The landscape of industry standards is evolving rapidly. Where SF6 gas once played a pivotal role in insulating transformers and switchgears, the industry is now transitioning to more climate‑friendly, CO₂‑based gas mixtures or greener alternatives such as for example nitrogen, CO2, and Green Gas for Grid (g3). This shift requires advanced sealing solutions.

More news on the subject Sustainability

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.